The Espresso Marathon: How We Used Lean Six Sigma to Serve 118 Drinks in an Hour

Signature Drinks

His

Inspired by crisp mountain mornings and golden fall foliage, this latte combines espresso, maple, and a hint of smoke for a cozy campfire essence. Each sip evokes Wyoming’s rugged landscapes and the warmth of autumn in the high country.

Hers

A smooth blend of espresso, locally inspired honey, and a touch of rosemary — this latte captures Oklahoma’s warm, earthy charm. The floral sweetness and herbal aroma offer a comforting nod to the state’s prairies and simple, grounded beauty.

Phase 1: Define the Value and the Bottleneck (D-M-A-I-C)

The wedding was expecting 100 to 140 guests. I looked at my single workhorse, the Breville Express Pro, and quickly realized we had a massive problem, a bottleneck that would lead to catastrophic wait times. On a single-boiler espresso machine, you can't brew espresso and steam milk at the same time. The machine has to heat up significantly between tasks. My estimated time for a single, complete latte was 2:30 to 3:30 minutes. My internal calculation looked grim: at that rate, we could only serve about 17–24 drinks per hour. With 100+ guests needing coffee during a one-hour cocktail period, the line would be chaos. This was a classic Lean Six Sigma issue: low throughput due to necessary sequential steps and non-value-added waiting time.

Phase 2: Measure and Analyze the Waste

The real killer in my workflow was the milk steaming and temperature recovery time: Milk Steaming (Express Pro): 1:00 to 1:30 minutes. To make this dream work on a small budget, we had to eliminate this non-value-added waiting time.

Phase 3: Improve the Process with Strategic Gear

Our solution was a perfect example of poka-yoke (mistake-proofing) and resource optimization. We used our budget to acquire two more machines—a Breville Bambino and, critically, a Bambino Plus—plus three Hario V60 pour-over kits.

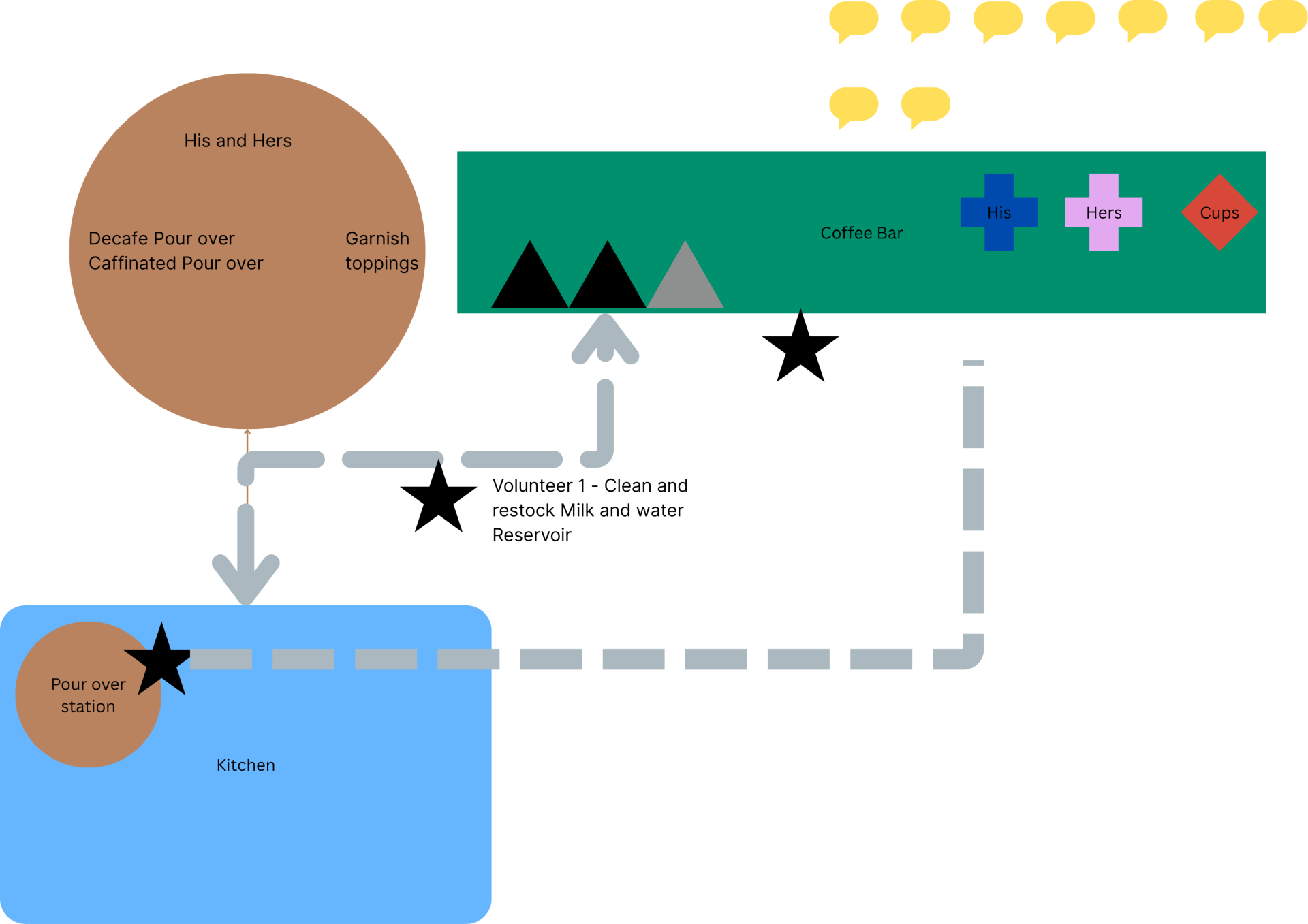

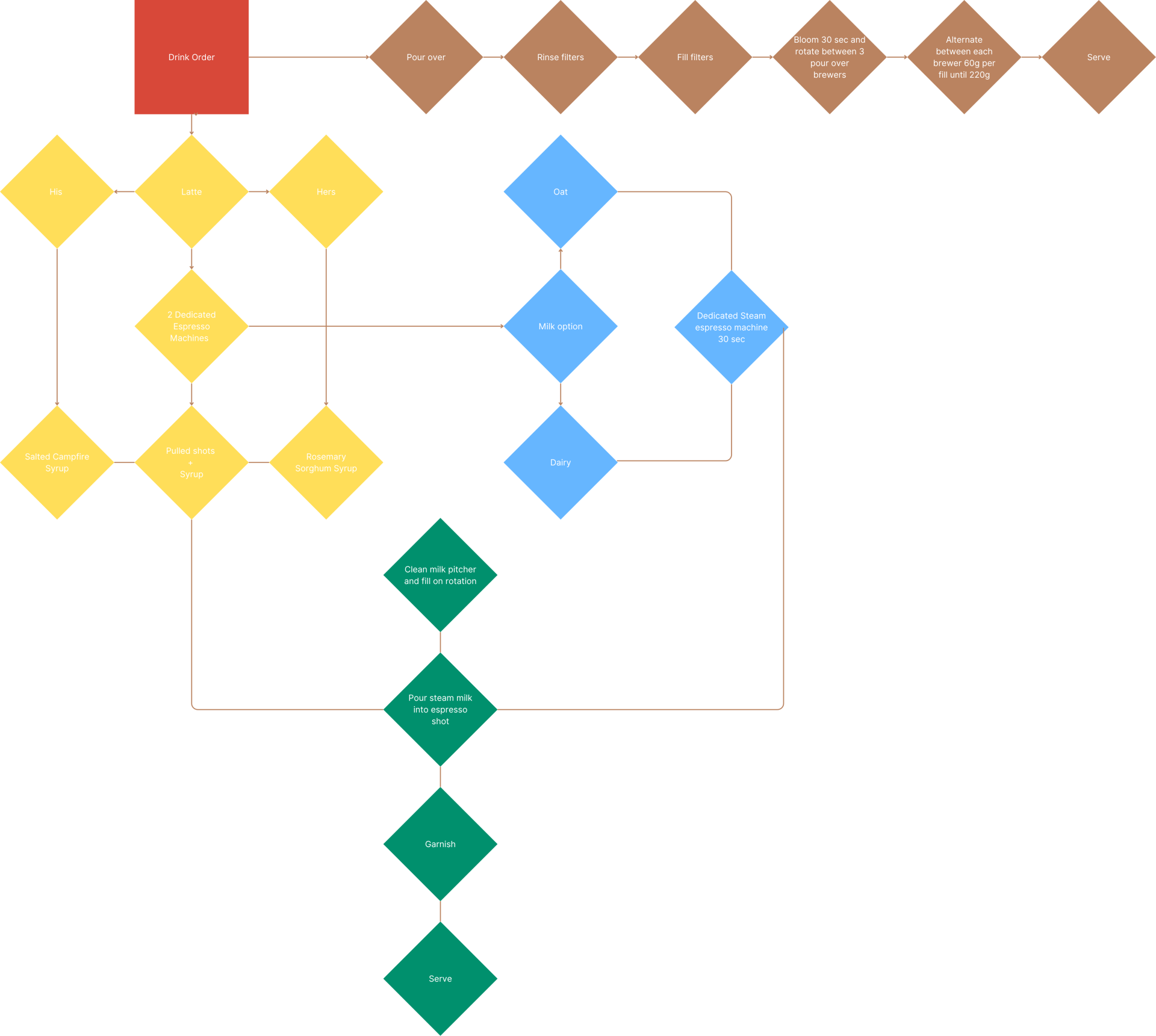

We engineered a specialized, parallelized workflow:

Dedicated Steaming: The Bambino Plus was assigned exclusively to steam milk. It uses a super-fast ThermoJet system, cutting the critical steaming time to around 30 seconds. This single change slashed the steaming bottleneck by 50–67%.

Dedicated Shot Pulling: The Express Pro and the standard Bambino were used strictly for pulling espresso shots. This eliminated the minutes lost switching the boilers back and forth.

Support and Flow: My amazing wife took on the role of "Pitcher Runner," constantly cycling milk pitchers to the wash station and refilling them. We also designated a volunteer to run the pour-over station to manage the demand for non-latte drinks.

Phase 4: Control and Execute the Marathon

The moment the ceremony finished, the crowd descended. The line was immediately out the door. I had to focus on the core Lean principle: Just one at a time. The workflow proved incredibly efficient. My two-machine espresso station was constantly delivering shots, while the dedicated Bambino Plus was rapidly steaming the milk pitchers. The moment the pour-over demand slowed, we implemented a final, crucial efficiency: The pour-over volunteer became a Prep Assistant, taking over the messy, intermittent task of emptying and loading the portafilters for the shot pullers. This final move smoothed the entire flow, allowing me to focus solely on the finishing touches—steaming and garnishing—and, most importantly, actually engaging with the guests!

The Result: A Lean Victory

Within one hour, we had successfully served 118 drinks (96 lattes and 22 pour-overs).This incredible throughput—a service rate of about approx 30 seconds per drink—was made possible because we identified the single-boiler delay as our biggest "waste of waiting" and strategically used an inexpensive machine (the Bambino Plus) to parallelize the process. It wasn't just a coffee bar; it was a high-efficiency espresso production line built on a dream, a small budget, and the principles of Lean Six Sigma. It was an intense, glorious success!